Temperature control and insulation

The precise temperature control used in Enomatic and Soft System® allows their use in a wide range of phases: cooling, such as in traditional fermentation or specific cryomaceration or heating, such as in late/winter fermentation or malolactic fermentation.

Gortani winemaking machines can be insulated fully or partially with a layer of high-density polyurethane foam, applied to rigid plates or injected into the space between the vessel and the outer shell. Insulation guarantees minimal heat loss and significant energy savings.

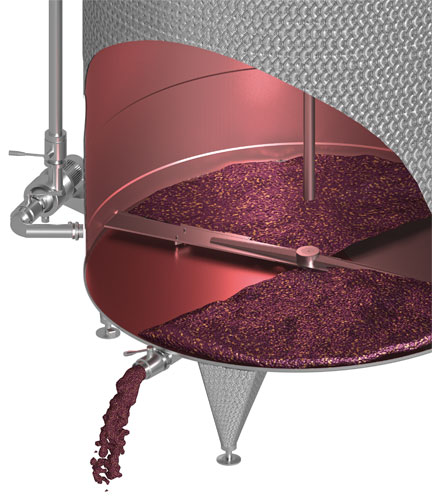

Gentle pump-over

Enomatic and Soft System® are equipped with an efficient pump-over system that draws the liquid from the bottom of the tank and sprays it onto the cap for complete and uniform homogenization of the liquid phase in a short time.

The system consists of a stainless-steel tapered rotor designed to protect product integrity, shut-off valves and a circuit branch T for separate drawing off.

The must flows to the rotary repulsion diffuser that sprays it evenly onto the cap, totally flooding the cap surface, for full contact between the must and the skin.

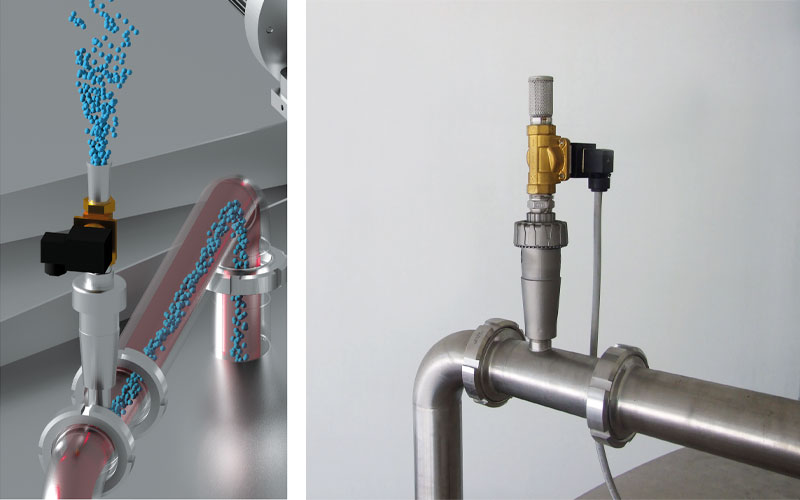

Ossigen

By dissolving a certain percentage of oxygen in the must, winemakers can influence alcoholic fermentation and the formation of stable pigments and enhance the wine’s fragrances. To meet this need to oxygenate the fermenting marc, Gortani has added its Ossigen system to Soft System®, drawing outside air into the winemaking machine and distributing it in the marc in a natural and controlled way to encourage the growth and survival of yeasts at the start of the fermentation phase. When in contact with air, the maximum amount of dissolved oxygen is around 8.0 mg/l.

Grape pip extraction

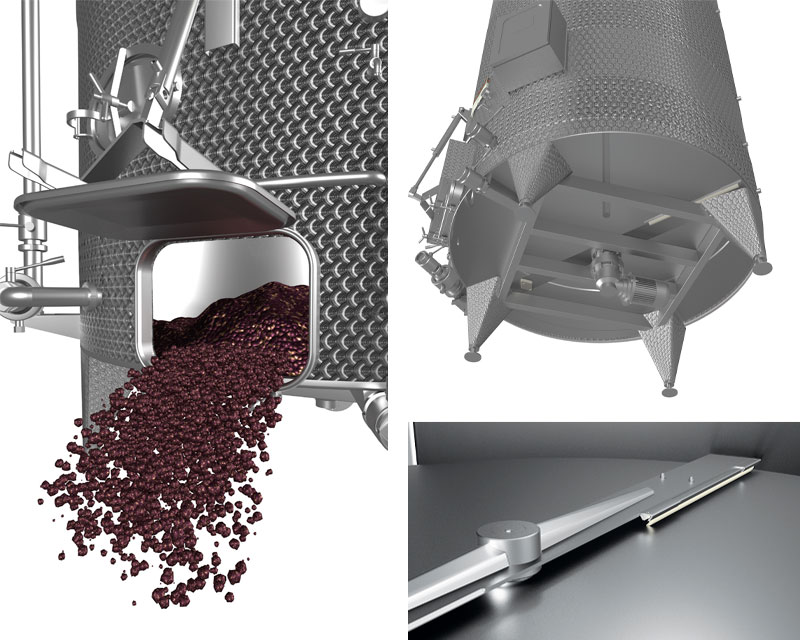

Grape marc discharge

Enomatic and Soft System® also make discharging marc easy and safe. Following the first pressings, powerful blades on the bottom of the winemaking machine automatically remove the grape marc with no need for labour-intensive manual operations. These blades are activated via the touch screen PLC and controlled by protection devices to guarantee maximum safety at every stage of extraction.