Your ally for

environmental,

economic and

social growth

About us

Gortani, a story that continues

A leading company for more than thirty years in winemaking technologies, Gortani is the international point of reference for the production of tanks for the storage of food liquids.

Gortani is synonymous with reliability in products, deliveries and pre- and post-sales service.

The production processes are highly automated, the craft activity becomes an industrial reality with very high quality workmanship. The company is very attentive to the choice and traceability of materials, components and processes.

Always a step ahead.

A story of innovation

1967

Inizia la produzione dei primi serbatoi

1981

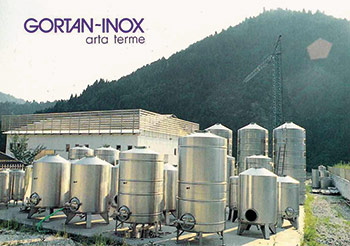

Creation of the first company dedicated to the construction of tanks in Arta Terme

1989

Creation of Arta Terme Gortaninox, specializing in advanced winemaking technologies and led by Gian Paolo Gortani

1998

Gortaninox becomes Gortani S.r.l.

2001

Gortani patents its Soft System®, the autonomous winemaking and plunging system that reflects the company’s knowledge and technical and innovative capabilities

2002

The company opens a modern production plant at the new Amaro site, strategically located to manage product distribution

2003

Gortani attends SIMEI, the International Enological and Bottling Equipment Exhibition, for the first time

2006

Gortani begins producing sparkling wine pressure tanks, a sector destined to become a driving force in the wine market thanks to the global popularity of bubbles

2010

Gortani’s commitment to sustainability takes shape in its first 195 kWh photovoltaic plant to reduce the company’s CO2 emissions. A first step for the company toward energy autonomy

2012

To meet the needs of its largest orders, Gortani creates its “Large Systems” division, for the safe machining of large tanks and pressure tanks

2015

Thanks to investments in automated systems, Gortani is able to produce one pressure tank every day

2017

The first fully insulated 3,000 hl tank is manufactured in the “Large Systems” division

2019

The company’s growth and its ability to respond quickly to market demands increases its need for more experienced workers, bringing the number of employees to over 200

2021

Gortani opens its doors to Industry 4.0 by renovating its equipment fleet to adapt to the needs of higher quality production, with material tracking and machining

2022

The company’s determination to reduce its environmental impact leads it to install a second 450 kWh photovoltaic plant

2023

Production planning and scheduling software is used to fully control individual factory processes and simplify complex decision-making. Reduction of the use of paper and other activities related to corporate social and environmental responsibility

1967

Tank manufacturing begins

1989

Creation of Arta Terme Gortaninox, specializing in advanced winemaking technologies and led by Gian Paolo Gortani

2001

Gortani patents its Soft System®, the autonomous winemaking and plunging system that reflects the company’s knowledge and technical and innovative capabilities

2003

Gortani attends SIMEI, the International Enological and Bottling Equipment Exhibition, for the first time

2010

Gortani’s commitment to sustainability takes shape in its first 195 kWh photovoltaic plant to reduce the company’s CO2 emissions. A first step for the company toward energy autonomy

2015

Thanks to investments in automated systems, Gortani is able to produce one pressure tank every day

2019

The company’s growth and its ability to respond quickly to market demands increases its need for more experienced workers, bringing the number of employees to over 200

2022

The company’s determination to reduce its environmental impact leads it to install a second 450 kWh photovoltaic plant

1981

Creation of the first company dedicated to the construction of tanks in Arta Terme

1998

Gortaninox becomes Gortani S.r.l.

2002

The company opens a modern production plant at the new Amaro site, strategically located to manage product distribution

2006

Gortani begins producing sparkling wine pressure tanks, a sector destined to become a driving force in the wine market thanks to the global popularity of bubbles

2012

To meet the needs of its largest orders, Gortani creates its “Large Systems” division, for the safe machining of large tanks and pressure tanks

2017

The first fully insulated 3,000 hl tank is manufactured in the “Large Systems” division

2021

Gortani opens its doors to Industry 4.0 by renovating its equipment fleet to adapt to the needs of higher quality production, with material tracking and machining

2023

Production planning and scheduling software is used to fully control individual factory processes and simplify complex decision-making. Reduction of the use of paper and other activities related to corporate social and environmental responsibility

History

The family is the heart of the business, the territory is the center of gravity.

“Our story began with grandfather Gian Pietro. It was he who began this tradition in the 1960s. Dissatisfied with the wooden barrels to produce Sliwovitz, the plum distillate, he had looked for a steel tank to take as a model to start a own production. With the collaboration of craftsmen and with the raw material purchased, he created the first steel tank.

Little more than a boy, his son Gian Paolo took over the management of the business, dedicating himself exclusively to the production of tanks, winemakers and autoclaves.

It was exactly from that moment that Gortani products began to enter the winemakers’ cellars.

Growth continuity

With Gian Paolo Gortani at the helm, the company continues to grow thanks to the commitment, improvement and maintenance of the values that have characterized its history.

The Amaro site has undergone two significant expansions with the aim of optimizing the production layout and introducing a whole series of improvements.

In 2012 Gortani inaugurated the “Large plants” division, designed and organized to deal with demanding and ambitious orders, which meet the needs of companies of industrial dimensions.

Today, the position of the Carnic company has consolidated as a global market leader, so much so that the Gortani brand is present in cellars on five continents.

History

The family is the heart of the business, the territory is the center of gravity.

“Our story began with grandfather Gian Pietro. It was he who began this tradition in the 1960s. Dissatisfied with the wooden barrels to produce Sliwovitz, the plum distillate, he had looked for a steel tank to take as a model to start a own production. With the collaboration of craftsmen and with the raw material purchased, he created the first steel tank.

Little more than a boy, his son Gian Paolo took over the management of the business, dedicating himself exclusively to the production of tanks, winemakers and autoclaves.

It was exactly from that moment that Gortani products began to enter the winemakers’ cellars.

Growth continuity

With Gian Paolo Gortani at the helm, the company continues to grow thanks to the commitment, improvement and maintenance of the values that have characterized its history.

The Amaro site has undergone two significant expansions with the aim of optimizing the production layout and introducing a whole series of improvements.

In 2012 Gortani inaugurated the “Large plants” division, designed and organized to deal with demanding and ambitious orders, which meet the needs of companies of industrial dimensions.

Today, the position of the Carnic company has consolidated as a global market leader, so much so that the Gortani brand is present in cellars on five continents.